Tools

I am a minimalist at heart so I try not to acquire things that don’t serve a purpose. A consequence of this is that I keep very few tools and I find ways to make my tools serve multiple functions. However, over the course of time it is inevitable that additional tools may be needed to complete a project. So, with that in mind, I am keeping a running list of all the tools I currently have and use. Hopefully, this will be a useful resource for those starting out that may not have the resources to purchase a garage full of tools and need to start small as I did.

MARKING & MEASURING

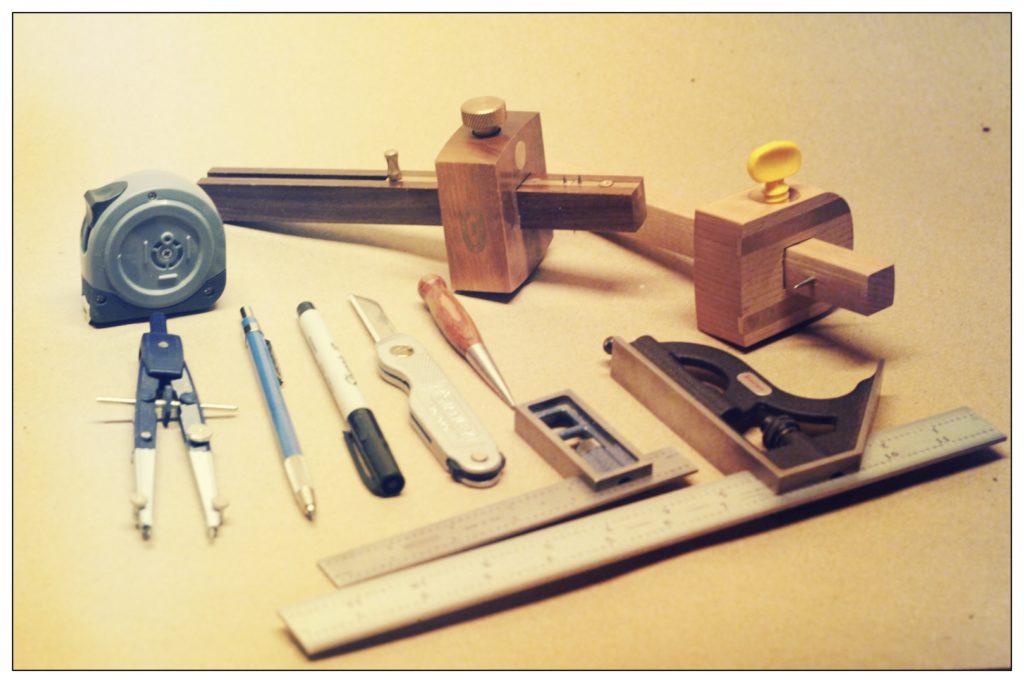

You won’t get anywhere without being able to measure out and mark your pieces. The standard equipment here is tape measures, rulers, and pencils. However, the pieces I want to point out specifically are the squares and marking gauges. New or antiques, as long as they’re in good shape.

Squares are absolutely important because everything you do requires pieces to be square. A good square is worth its weight in gold because a bad square that appears inaccurate by only a fraction of an inch, will multiply the error as size increases. A single combination square is the only real essential square needed in the beginning. Eventually, you could move onto small try squares or large framing squares, but those would be more for luxury and efficiency.

Marking gauges are the other essential tool in this category. They are remarkably simple tools consisting of a wooden beam, a wooden fence, and a small metal pin. Their purpose is to mark the wood with a thin line of broken fibers that your saw or chisel can follow. There are various types of gauges old and new, but a single pin gauge is sufficient to get you started.

SHARPENING

Sharpening is a crucial skill that I recommend you get comfortable with as soon as possible. I also recommend you don’t be frugal with this purchase. Most tools consist of a sharp metal cutting edge. When that edge dulls, your tool will no longer function properly. It’s not uncommon to need to sharpen tools several times throughout a larger project so you can start to see why it’s so important.

The argument between oil stones, water stones, diamond plates is mostly nonsense. From my experience, they all work so you just need to find the one that works for you. I have chosen diamond plates because they are the least messy, don’t require flattening, and I think are the easiest to use. Find what works for you and master it.

An additional tool here is the honing guide. All cutting edges have a primary bevel angle and those angles are determined based on the tools use. The honing guide is an apparatus that will hold the steel to maintain that angle so you can sharpen with ease. Eventually, you’ll be able to scrap the honing guide and sharpen by hand, but in the beginning it helps you get the sharpening done so you can get back to work.

SAWS

After you’ve measured and marked out your pieces and everything is sharp, it’s time to cut. These are also tools that could be purchased new, used, or antique as long as they are sharp and straight.

Most cutting you’ll do in the beginning will be rough cutting lumber into smaller pieces and cutting joinery. A basic panel rip saw will do just fine with the former and a dovetail saw will handle most of the latter. Many people will also recommend carcass saws and crosscut saws and all that, but from my experience I can say those are mostly unnecessary. Rip saws will crosscut just fine as long as you marked your pieces properly.

As you progress in your skills and begin to build more complex pieces, you can eventually include a tenon saw and a coping or fret saw. A tenon saw will allow you to cut larger joinery and a coping or fret saw will cut curves, tight corners, and small joinery.

HAND PLANES & SCRAPERS

I group together hand planes and scrapers because they are all surface preparation tools, rough all the way to final. In the beginning, only a good, single hand plane will get you by, but as you decide to start dimensioning lumber you’ll need additional hand planes.

The hand plane is the most iconic woodworking tool. Most people recognize it even if they don’t know what it is. The most popular is probably the #4 Stanley hand plane. These can be found in antique stores or estate sales just about anywhere. You can also purchase a new one from other manufacturers. This is a very important tool in the all hand tool workshop so don’t skimp here. One of the first things you might discover with a hand plane is tearout. Planing in the wrong direction could cause quite a bit of tearout so learning how to read grain will help with this and I’ll cover that another place and time. In the meantime, you’ll likely hear the terms bevel up, bevel down, low angle, high angle. For the most part it mostly won’t matter. To start, I would say that a #4, #5 or low angle jack plane will suffice. You will eventually obtain more planes as you figure out your workflow so any plane you get now will still have a use later.

Scrapers are more of a luxury item in the beginning. If you’re careful and observant, you can get by with just a hand plane for a final finish. However, As you start dealing with tearout, you’ll discover that card and cabinet scrapers will operate in the areas that hand planes won’t. When a hand plane starts digging in and causing tearout, you can just put it aside and grab the scraper. A scraper can also handle smaller areas and areas that aren’t flat.

CHISELS

Chisels are some of the oldest tools of civilization. Most work you do will consist of cutting, planing, or chiseling. It’s quite possible you will use chisels constantly throughout most projects. They will generally be used in chopping joinery although they can be used for other small tasks.

Chisels are another tool you don’t want to be frugal with. There are some cheaper chisels on the market that will hold up so shop carefully. The good news here is that you don’t need many of them. It’s hard to know where to start when you are looking around. So many chisel brands and types ranging from firmer, mortise, skew, etc. A basic set of bevel edge chisels will get you by for quite a while. Handle type (tang, socket) is irrelevant. Steel type (O1, A2, PMV-11) is also irrelevant. Good chisels will sharpen well, assuming you invested in good sharpening stones, and they will hold an edge just fine.

As for sizes, only a few are really necessary. As you can see above, I only have 4 (1/4″, 3/8″, 1/2″, 3/4″) and they have handled most anything. A lot of joinery is determined by chisel sizes so in the event you need to cut a 5/16″ mortise, that’s the point when you purchase that chisel. Don’t buy it until you actually need it. Otherwise, keep them sharp and flat and they will last for a long time.

TO BE CONTINUED…