Bench Hooks

Regardless what kind of woodworker you are or what projects you make, there will be times when you need to saw or chisel small parts and boards that may not fit in your vise. This is where bench hooks become a nice luxury. They have multiple other uses, but I think these will be the two most frequent day to day. These can usually be made by just nailing a few pieces of wood together, but I generally like my tools and projects to be a bit more pleasing to the eye. Below I will show you how to create a pair of bench hooks using solid Maple.

TOOLS

Required:

- Hand Plane (#4, #5, Low Angle Jack, etc.)

- Panel Saw

- Dovetail or Gent Saw

- Marking Knife

- 3/4” Chisel

- Mallet

- Straight Edge

Optional:

- Card Scraper

- Sand Paper

- Rasp / File

INSTRUCTIONS

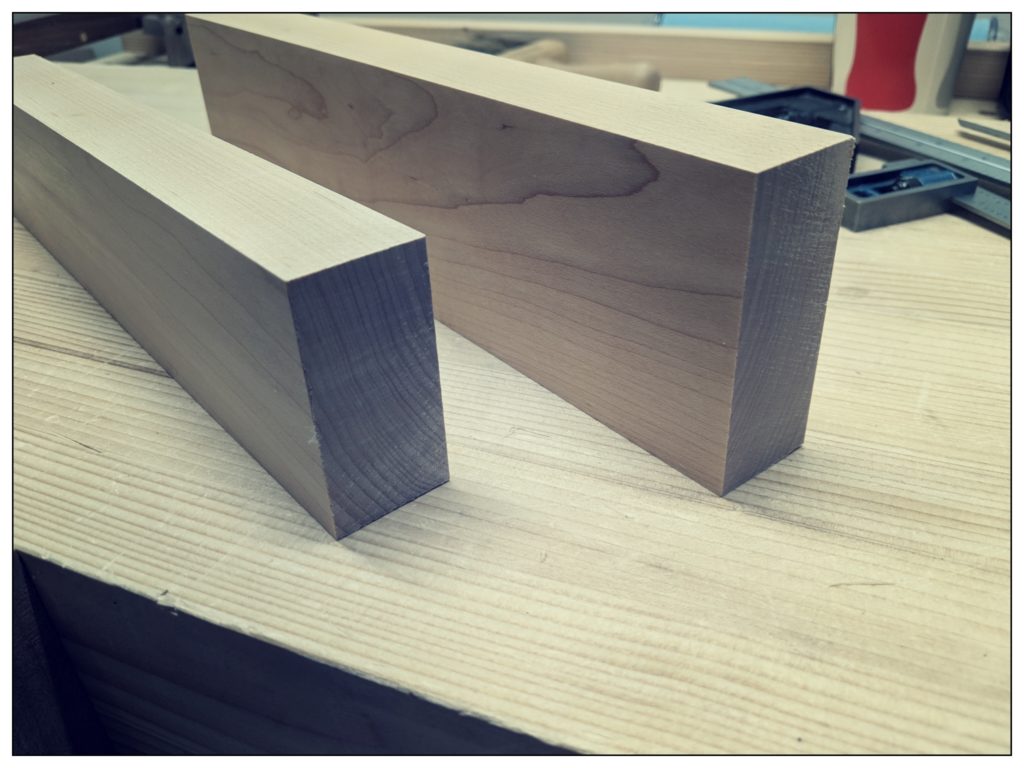

I start this project with a long piece of 5/4 Maple. You could go thicker, but I’d try not to go much thinner. The thickness will determine the thickness of the hook and its grabbing ability. I cut out two pieces both about 12″ long. One will be about 3″ wide while the other will be 2 1/2” wide. This isn’t mandatory, but close enough should suffice.

Once both pieces are cut out, take your hand plane and plane all faces, sides, and ends. Since there are no joints or joining surfaces, straight and square isn’t absolutely necessary, but this is a good place to practice planing square and straight. Try and get it close, but a little off won’t affect anything.

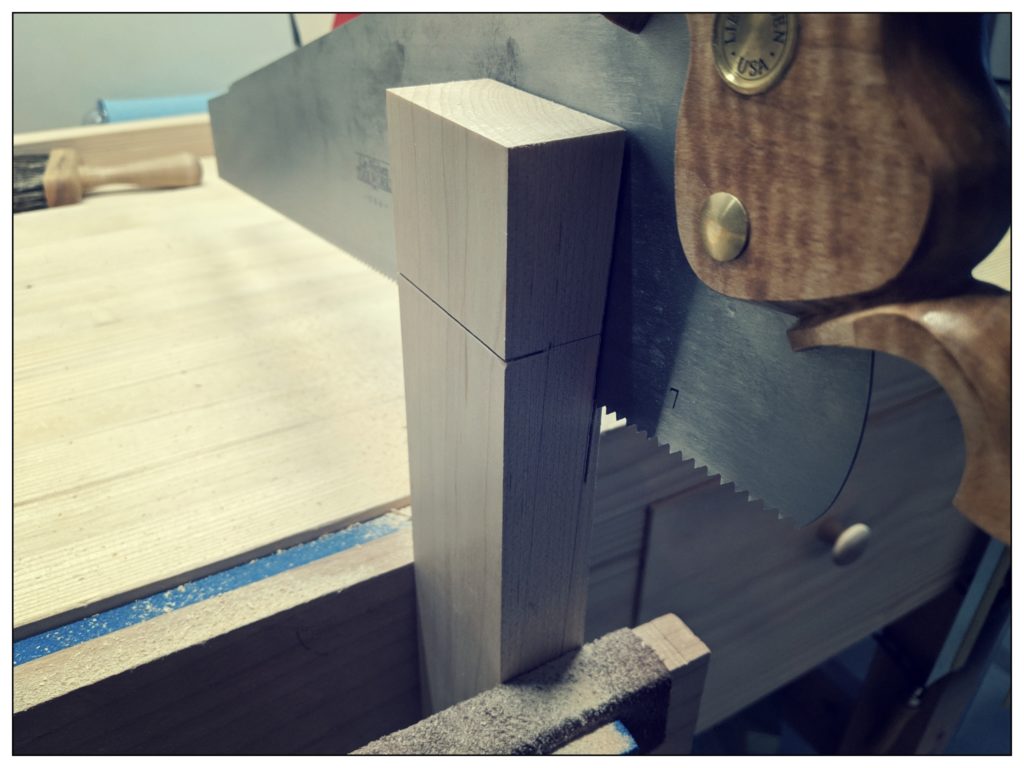

The next few steps will be the same for both pieces. First, measure in from the end about 2″ or 3″ and score a perpendicular line. Do this also on the opposite end of the opposite face. From that line, you’ll score another line down each side about 1/2“. With this done on both sides, connect the small line to the far corner on the same face. Do this for both sides and you’ll get what looks like a very tall “Z”. Using the dovetail saw cut down the two short lines on each side. Then, using the panel saw, cut down the long lines to meet the short ones you just cut. When cutting the long side, you can clamp a piece of scrap against the corner to get the cut started. The image above shows the short cut already made and the long cut in progress.

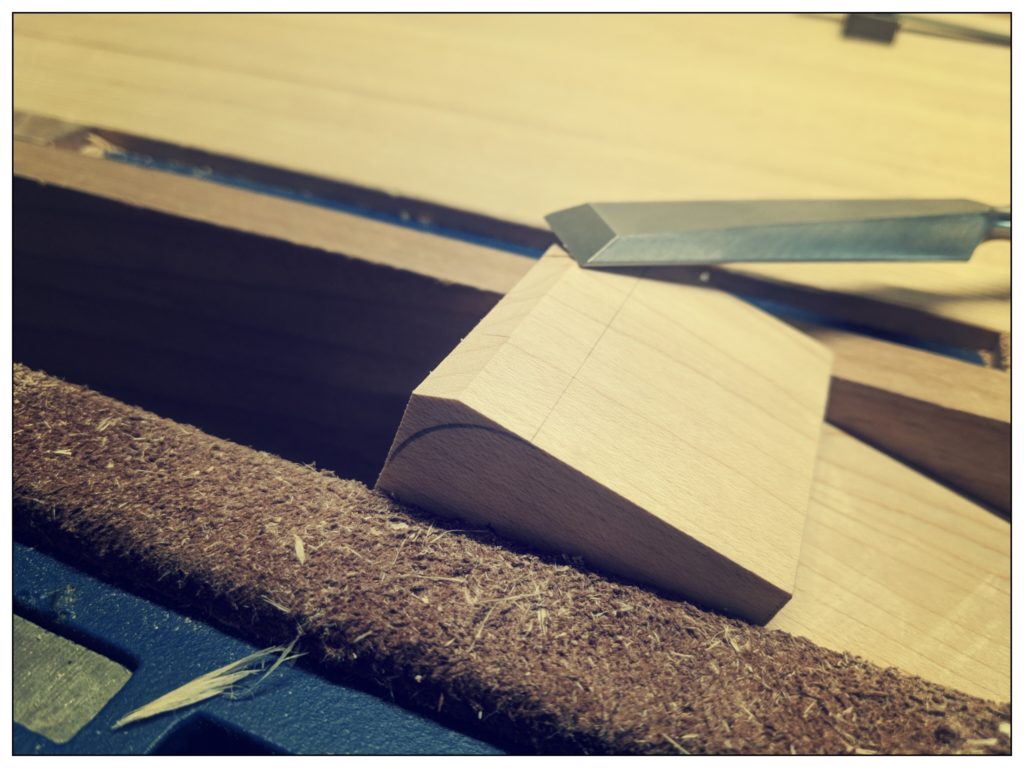

Once the waste has been removed, grab your plane and take light passes at a diagonal to clean up the saw marks. You won’t be able to hit the full area so feel free to use a card scraper or rough sand paper to help shape it. Do this to both sides.

Technically, once the last step is complete you have a rough bench hook. This step is completely optional and done more for appearance than anything. It does, however, make the hooks feel better in the hand so it’s up to you. Here, we round off the outer hook corner. As you can see, I took a small radius and marked it out. Using my largest chisel, I take small chops to take off the corner. Don’t go too heavily here, just small bites are good. I do this in several passes until I have a rough, rounded corner.

Now using a rasp and file, start to slowly smooth over the corner. You can use sand paper here as well moving from rough to fine grits.

OK, almost done. Last step is to take a notch out of the widest hook. Pick a side and cut away about 1/2″ from the hook. The hook itself acts as a fence while the notch acts as a channel that your saw will ride in. This will be useful when you use the bench hooks for cutting small parts. Also, this will protect your bench because if you oversaw it will go into the hook and not your bench. It’s also recommended you also use your plane to take off all the corners and edges.

As you can see, the rear hook is the part that will overhang your bench and hook onto it. This will allow you to push against it and it will stay put. For very small pieces you can use the one large hook, but with longer pieces you can place them on the bench together spaced apart to act in unison. If you decide to put a finish on them, just an oil is sufficient. Since these are basically shop devices a finish isn’t needed. That’s it! We’re done.